If you have a great product idea, the first step is to create a prototype to test and refine your design before moving into production. A prototype is a working model of your product that allows you to see how it looks, feels, and functions in the real world. Let’s have a look at some different stages of product development, from prototype to mass production, and explain how to create a product prototype.

Creating a Product Prototype

The purpose of creating a prototype is to test and refine your product design. This usually involves making 1-10 units of the product over a few weeks to months, at a relatively low cost to the creator.

Creating a product prototype is an essential step in the product development process. It allows you to test and refine your design, identify any flaws or issues, and make necessary improvements before moving into production, thereby avoiding costly mistakes en masse.

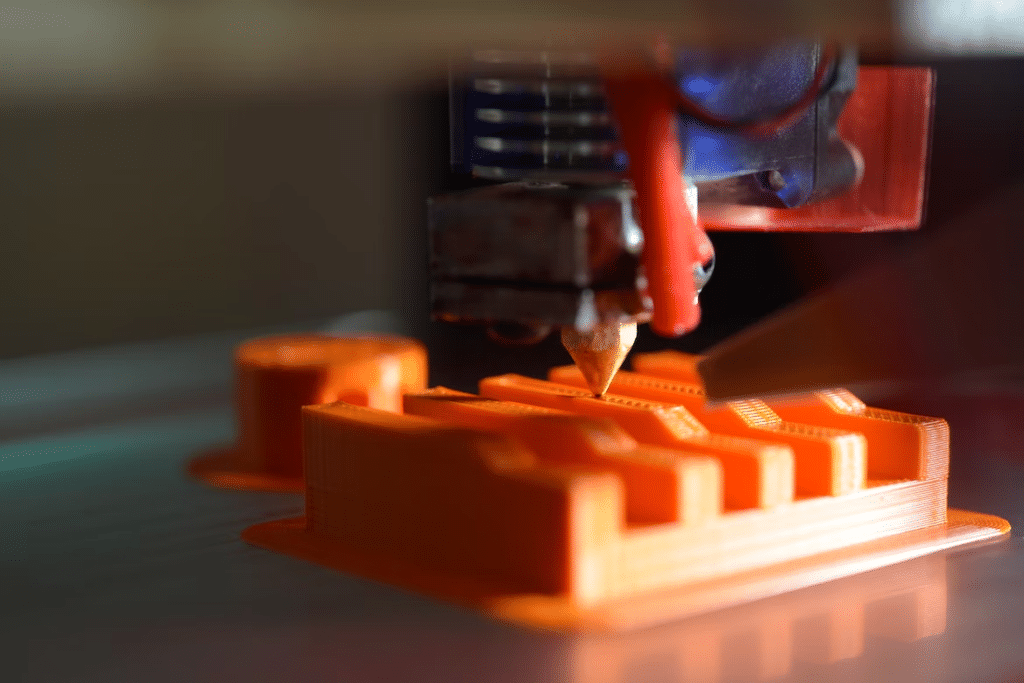

Traditionally, creating a product prototype was a time-consuming and expensive process that involved creating moulds or other tooling to manufacture a small batch of prototypes. However, with the advent of 3D printing, the prototyping process has become much easier and more affordable – and more accessible too!

3D Printing for Prototyping

3D printing, also known as additive manufacturing, is a process of creating three-dimensional objects by depositing layers of material. This can be done in a number of ways, usually by either melting a filament and extruding it with a filament printer, or by using a UV curing system under a print bed to set layers of resin into a detailed model on a resin 3D printer. This technology has revolutionised the prototyping process by allowing designers to quickly and easily create physical models of their designs, even from their own homes and small offices.

Rapid Prototyping vs. 3D Printing

Rapid prototyping is a term that is often used interchangeably with 3D printing. However, there is a difference between the two. Rapid prototyping refers to any process that allows designers to quickly create physical prototypes of their designs. 3D printing is a specific type of rapid prototyping that uses a layer-by-layer approach to create objects.

While 3D printing is a popular choice for prototyping, there are other rapid prototyping methods available, including CNC machining, vacuum casting, and injection moulding. Each method has its own advantages and disadvantages, and the best choice will depend on the specific needs of your product.

Moving Into Production

The production process is intended to test your production process and validate your design, usually over the production of between 10 and 1000 units. This process again takes weeks to months to complete, this time at a moderate cost to the producer. Once you have created a product prototype and tested it thoroughly, you can move into the production phase. There are two main stages of production: production and mass production.

Production is the stage where you manufacture a small batch of products for testing and validation. This stage is often referred to as low-volume production and allows you to identify any issues with your production process or design before moving into mass production.

There are several types of production that are used professionally. Here are a few examples:

Custom production

Custom production involves creating products that are made to order based on specific customer requirements. This type of production is often used for specialised products that require unique features or specifications.

Batch production

Batch production involves creating a specific number of products at a time. This is often used for products that are made in large quantities but not in continuous production.

Just-in-time production

Just-in-time production involves producing products only when they are needed, rather than creating a large inventory of products in advance. This helps to reduce waste and minimise storage costs.

Mass Production:

This stage is aimed at manufacturing a large number of products (thousands or even millions) for commercial sale, over many months or years, and with high cost.

Mass production is characterised by its high volume output and low unit costs. It typically involves a series of interconnected assembly line stations, each of which performs a specific task in the production process – this stage of production does not occur in the home office, unless you live at a warehouse!

One of the key advantages of mass production is its efficiency. By standardising production processes and using specialised machinery, manufacturers can produce products at a much faster rate than would be possible through manual labour. This can help to reduce costs and increase productivity, making it easier to produce large quantities of products at a low cost. Unfortunately, it can also reduce the customizability of your product line. This is where mass customisation comes in.

Mass customisation

Mass customisation involves creating products that can be customised to meet individual customer needs, while still maintaining the efficiency of mass production. This is often used for products that have a large number of potential variations, such as clothing or furniture. It involved making multiple variations on interchangeable parts, so that different products can be assembled using common parts – think Lego or IKEA!

When deciding which stage of production to focus on, it’s important to consider your goals and resources. If you are a startup or small business, it may be more practical to focus on low-volume production to minimise risk and conserve resources. You can easily build up to larger-scale production as your business grows.

Understanding the different stages of product development is crucial for any creator looking to bring a product to market. Creating a product prototype is an essential step in this process, and 3D printing has made prototyping easier and more accessible than ever before.

Whether you are working on a small-scale production run or planning to manufacture thousands of units, understanding the different stages of production will help you create a successful and profitable product.